Copyright © WHERE, Inc. All Rights Reserved.

SOLUTION

Business&Industry IoT&Digital Transformation

Business DX by the EXBeacon Platform

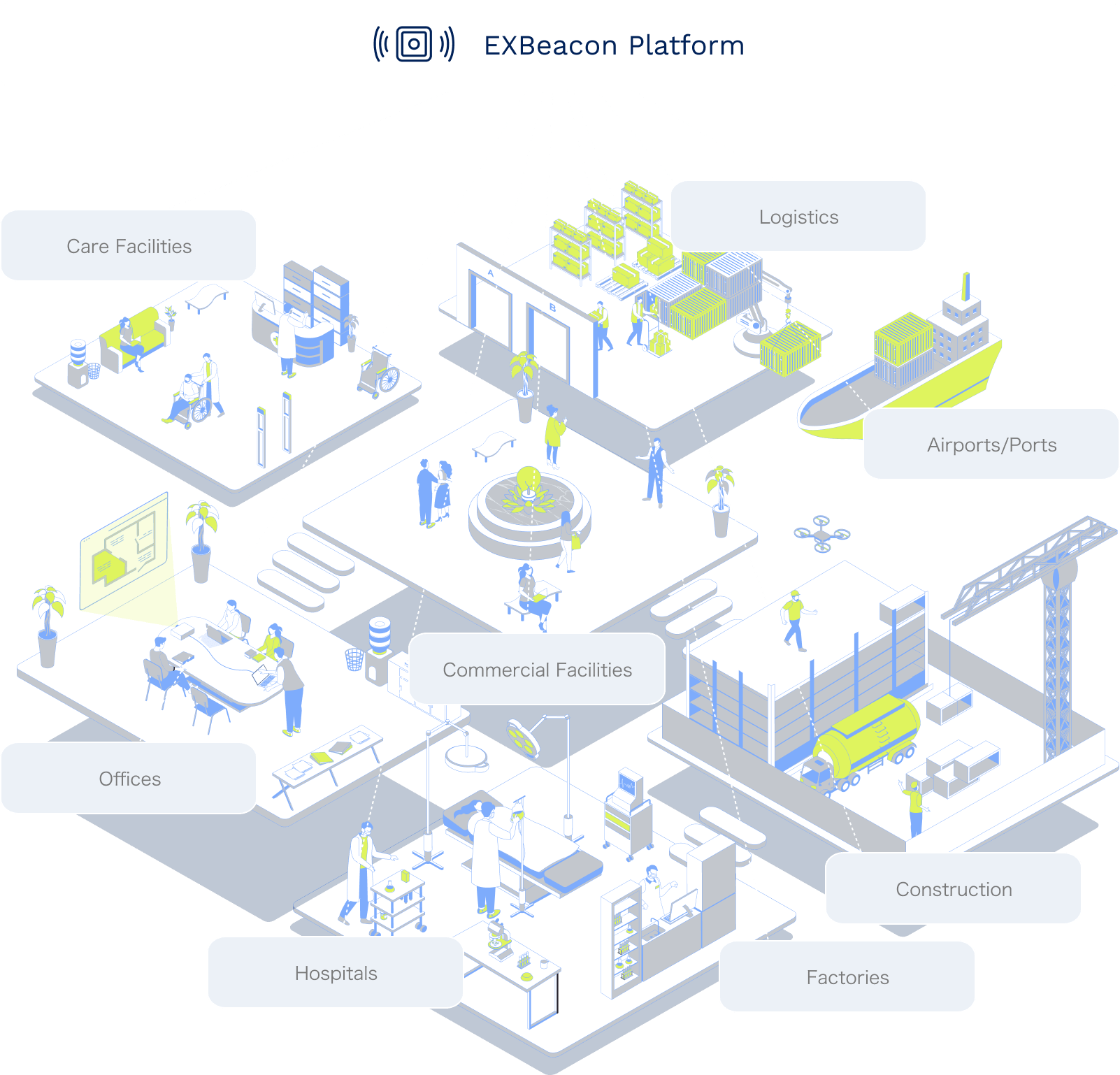

Built on the EXBeacon Platform, this IoT foundation extends across offices, hospitals, factories, logistics hubs, commercial facilities, and other environments—connecting people, equipment, spaces, and systems into a unified operational layer. It supports everything from factory performance monitoring and warehouse inventory visibility to utilization analytics in hospitals and retail facilities. Powered by connection and data, it raises the value of every building and enables new experiences and smarter ways of operating.

The EXBeacon Platform gives buildings the ability to connect and operate digitally. By linking diverse building environments and business operations through data, it enables services optimized for the unique characteristics of each facility.

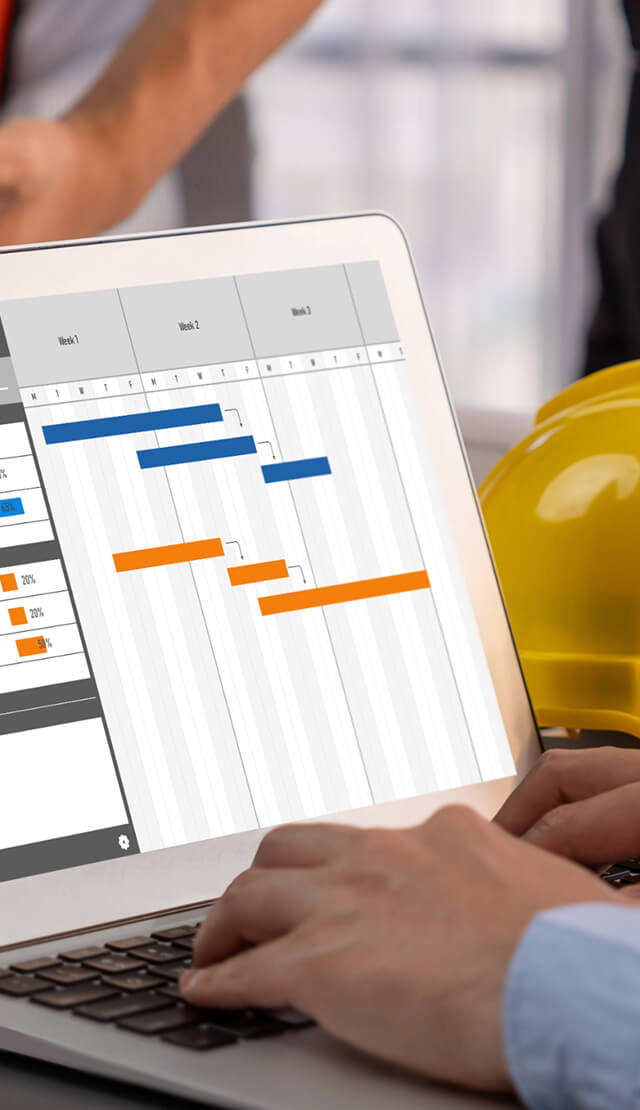

At construction sites, confirming the location of temporary materials and aerial work platforms and coordinating their reservations required significant effort, with issues such as loss and incorrect returns being common. By introducing “MonoBooker,” a site-equipment reservation solution powered by the EXBeacon Platform, location and utilization statuses are visualized, and reservations can be made from anywhere.

Effects

Temporary materials can now be located at a glance, eliminating the need for search time.

Aerial work platforms can be reserved from anywhere, reducing the burden of scheduling and coordination.

Analyzing utilization data has made it possible to determine appropriate equipment quantities and understand actual usage rates.

These improvements have significantly contributed to cost reduction and greater operational efficiency.

Scope of WHERE’s Services

Positioning infrastructure powered by the EXBeacon Platform

Detection of location and utilization status via BLE tags and receivers

Temporary-material reservation system (booking&utilization tracking)

Real-time visualization and analytics through dashboards

In manufacturing plants, manually entering work records and checking progress required significant effort, leading to delays and added burden.

By integrating the TECHS production-management system from Technoa with the EXBeacon Platform, the “Ez-Bee” solution automatically captures performance data based on the positions of workers and work orders, visualizing progress and location information in real time. This has improved productivity and enhanced decision accuracy.

Effects

Start and completion times are automatically captured, reducing the need for manual daily-report entry.

Progress is visualized in real time through “location × performance” data.

Eliminating unidentified or misplaced items reduces search effort and time.

Scope of WHERE’s Services

Positioning infrastructure powered by the EXBeacon Platform

Work-status detection via beacon cards and beacon boxes

Performance data management and dashboards through cloud integration

Support for data integration with the TECHS series

In cell-production manufacturing plants, it was difficult to track worker progress and time spent at each process, leading to bottlenecks, idle time, and staffing imbalances. By visualizing worker location and activity in real time and integrating this information with the production management system, work-performance data is automatically collected and analyzed, enabling optimization of process delays and workforce allocation.

Effects

Worker locations are tracked and process progress is visualized in real time.

Idle time and task imbalance are detected within minutes, enabling immediate response.

Work time is automatically aggregated, automating daily-report creation.

Identifying causes of process delays and operational stoppages, along with workforce optimization, delivers improvement effects equivalent to ¥1.5 million per month.

Scope of WHERE’s Services

Positioning infrastructure powered by the EXBeacon Platform

Acquisition of worker location and activity data via BLE tags

API integration with the production management system

Automation of process visualization and daily-report generation

At tunnel construction sites, it is difficult to keep track of worker locations and conditions in hazardous areas, making accident prevention and rapid response a challenge. By leveraging the EXBeacon Platform to track the real-time positions of workers and heavy machinery, functions such as entry control, location management, hazardous-area detection, and detection of workers alighting from machines provide site-wide safety visibility and help prevent risks before they materialize.

Effects

Worker and heavy-machinery locations and entry/exit status are captured in real time.

Hazardous-area entry and workers alighting from machines are automatically detected, with instant alerts helping to prevent accidents.

Site-wide conditions are centrally monitored via dashboards, streamlining safety checks.

Data analysis can also be used to improve safety planning and training.

Scope of WHERE’s Services

Positioning infrastructure powered by the EXBeacon Platform

Hazard detection and alert integration (PLC, lights, and buzzer control)

Real-time monitoring and analytics platform via dashboards